Case study: Fire proofing tank pit walls

"In all situations the analyses outcomes were positive" - Enrico Lammers, Pro6com

"In all situations the analyses outcomes were positive" - Enrico Lammers, Pro6com

Fire proofing of process installations is important, because when things go wrong, they go very wrong, very fast. The company Pro6com is specialized in (process) engineering and project management, primarily in the process- and pharmaceutical industries.  For one of their projects, pro6com asked Femto Engineering to help determine the integrity of two types of tank pit walls, during a hydrocarbon fire.

For one of their projects, pro6com asked Femto Engineering to help determine the integrity of two types of tank pit walls, during a hydrocarbon fire.

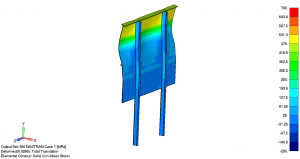

The walls of the tank pit are created with sheet piling and reinforced with horizontal beams that should prevent the overflow of fluids in case one (or more) of the tanks situated in the pit collapses. If the leaked flammable fluid catches fire, the situation could get critical. The following components where considered in the analysis; Hydrostatic pressure of the leaked fluids, the fire on top of the fluid heating the sheet piling, and the differences in temperature in the pit wall because of the cooling effect below the surface of the fluid.

For a complete analyses, two types of situations were considered. The first was the situation when the burning fluid reached the highest level of the tank pit and the second when the burning fluid remained halfway.  In the last occurrence the top part of the sheet piling was heated (a maximum temperature of 350 degrees Celsius was calculated which caused a drop of the yield stress) and the bottom part remained “cooled” by the fluids.

In the last occurrence the top part of the sheet piling was heated (a maximum temperature of 350 degrees Celsius was calculated which caused a drop of the yield stress) and the bottom part remained “cooled” by the fluids.

The outcome of the analyses were positive in all situations. Even though these kind of extreme scenarios rarely take place it’s good to know that the pit walls are able to withstand the hydrostatic pressure and the heating in both situations.

We hope you liked this case study. Want to hear more about our services? Contact us! Make sure you don’t miss any of our other posts by following us on Twitter, Facebook or LinkedIn.

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!