FIA and Motorsport: Safety evaluation of roll cages

Simulations as an alternative to testing without compromising on safety

Simulations as an alternative to testing without compromising on safety

The FIA (Fédération Internationale de l’Automobile), the international motorsport federation, plays an important role as a regulator and coordinator within the motorsport world. One of its responsibilities is to set safety standards that participating vehicles and its drivers must meet. An important part of this is the requirements for the roll cage. This construction provides the necessary driver protection for vehicles in motorsport.

From the past, it has been common practice for roll cages to undergo physical testing to determine whether they meet FIA safety standards. Therefore, this process initially involves creating a roll cage that is subjected to a series of destructive tests. An alternative approach is to conduct these tests using a Digital Twin in the virtual world. Simulations offer an efficient method for testing roll cages against FIA safety standards. This method provides significant advantages, including cost and time savings, as well as fast iterations. An additional benefit is the early identification of potential structural problems and the revelation of potential weight savings.

Femto Engineering has been FIA-accredited since last year, making it the only company in the Benelux region that verifies whether roll cage structures meet FIA safety standards through simulations. Our accreditation is included in the FIA’s Technical List 35, which comprises all accredited companies performing such simulations.

Using the 3D CAD design of the roll cage, a Finite Element Model (FE model) is created to accurately represent the mechanical behavior of the roll cage. By converting the geometry into an FE model, simulations can be set up to mimic the testing of the structure as it would occur in reality.

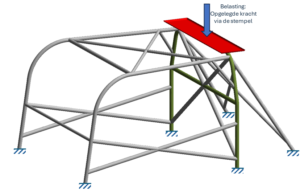

Additionally, it is crucial to apply the same boundary conditions in the FE model as in the physical tests. For instance, if the roll cage is fully clamped at the bottom during a test, the FE model must also have the structure fixed at the clamping location. Moreover, the contact points between the outrigger, used to apply the load, and the roll cage itself must be precisely positioned to match those of the physical test. Naturally, possible internal contact between the tubes of the frame is also considered. An example of the model in a specific test is illustrated in the figure below, where a vertical imposed displacement is applied.

The FIA mandates that all tube profiles of the roll cage must be constructed from 25CrMo4 alloy. As this material exhibits elastic behavior until reaching the yield strength, followed by plastic deformation, a linear elastic-plastic material model must be employed. This material behavior is replicated in the simulation using the true stress-strain curve of 25CrMo4.

By using a so-called explicit solver, both large plastic deformations and the possible occurrence of buckling in the tubes of the roll cage can be taken into account. The simulations are based on the ‘FIA Homologation Regulations for Safety Cages 2023’, where three tests are simulated. Based on the results, the strength and stiffness of the roll cage is determined and it can be concluded whether it meets the requirements set by the FIA. A possible outcome could also be weight savings, which could be very interesting for the manufacturer.

Three different tests are necessary for FIA approval, with the load per test determined by both the vehicle’s weight and its type. The FIA also mandates specific dimensions for the outriggers and the speed at which testing must occur.

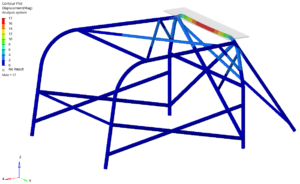

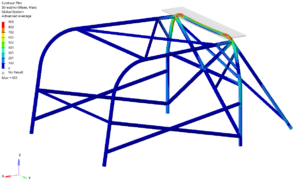

As previously mentioned, one of the tests involves imposing a vertical load on the roll cage via an outrigger, with an example simulation result provided earlier. For this type of roll cage, the prescribed load for this test is 70.5 kN. The FIA specifies a maximum deformation limit of 50mm. If the maximum deformation remains below this threshold and the structure remains intact without cracking, it meets FIA requirements.

The remaining tests follow a similar procedure.

Left: Displacement Right: Stress

When simulations confirm that the roll cage meets all FIA requirements, Femto generates a comprehensive report encompassing the model description, conducted simulations, results, and conclusions. This report serves as official certification that the roll cage complies with FIA standards. Typically, the turnaround time for such a project is less than one week.

Should the structure fail, recommendations for enhancements are made and rapid design iterations can be carried out using simulations. In other cases, the construction may be made lighter.

For questions or requests, please contact us using the form below or by phone.

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!