Fatigue analysis supporting the Panama Canal Expansion

A passageway meeting extreme requirements

A passageway meeting extreme requirements

The 81 km long Panama Canal connects the Caribbean Sea with the Pacific Ocean. Annually more than 14.000 ships use the canal, which means an average of 35 to 40 ships a day. For a new generation of container ships being able to pass through the Panama Canal, adjustments had to be made.

Since the commissioning of the Canal in 1914, the global flow of goods expanded and the average size of container ships has increased. For a new generation of containerships (capable to carry up to 12.000 TEU containers) the locks and the Panama Canal proofed to be too small. Therefore, the authorities of Panama decided to widen the Canal. This resulted in the Panama Canal Expansion Project kicking off in 2009. Part of the project was to build two new lock complexes, one on the side of the Caribbean Sea and one on the side of the Pacific. The new lock chambers are 427 meters (1400 feet) long, 55 meters (180 feet) wide and 18.3 meters (60 feet) deep.

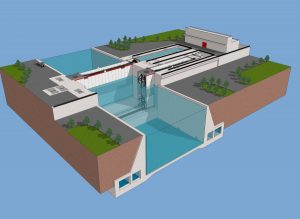

Impression of a lock

Both lock complexes consist of three lock chambers that convey the ships of sea level to the upper Gatun and vice versa. Between each lock chamber there is a double door. A total of 16 doors were placed, 8 doors per complex. The dimensions of the steel doors and the enormous weight (three thousand tons per door) are unique in its kind.

The forces that affect the fatigue of the gates and the requirements needed for the design of the doors made the calculation not only subject to a static load. It so happens to be that the lock complexes are situated above the St. Andreas Fault and therefor the danger for an earthquake is always imminent. The gates must be able to withstand an earthquake, but also the consequences of collisions of ships against the lock doors and the forces of the water itself. To make sure the locks could meet these requirements, they were analysed by means of finite element analysis.

Section of earthquake simulation model

The overall assessment was led by the IV-Group. Femto engineering was involved in an early stage to simulate the earthquake response with Fluid-Structure Interaction analysis, and at a later stage with the detail analysis of a part of the door which is called the buoyancy chamber or drift chamber. Based on the calculations, Femto recommended strengthening the cover on the doors on several places. Additionally Femto provided input for the weld reports. These were used as a guideline in the overall construction of the locks.

The Panama Expansion project was completed in the summer of 2016. Interested in what Femto Engineering could do for you? Get in touch!

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!