Spotlight on a intern: HEEDS

We always try to establish new innovative insights with our interns. So they deserve to be put into the spotlight.

We always try to establish new innovative insights with our interns. So they deserve to be put into the spotlight.

We love working with enthusiastic engineering students and give them the opportunity to work with our simulation specialists and tools. However, every year we have limited FEA and CFD internship positions available. In 2021, out of the many applications, we selected Jochem to join the team. If you would like to know what it’s like to be an intern at Femto Engineering, read about Jochem’s experiences here.

Name: Jochem Timmers

First day: 6 September 2021

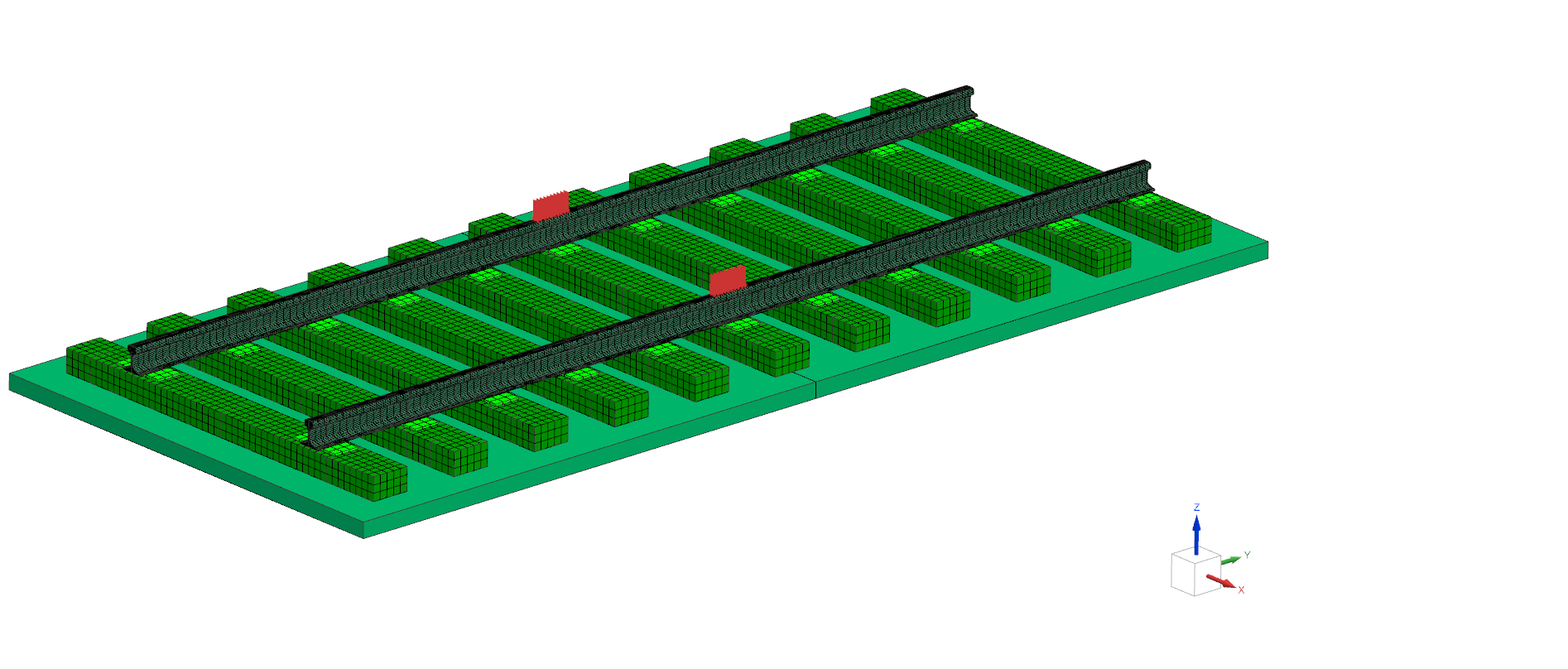

Title: Internship Lankhorst EP Plastic Sleepers

Last year, Femto Engineering gave a presentation for the 2nd year Automotive Engineering students of the Rotterdam University of Applied Science. During this presentation Tom Santegoeds and Patrick Naar explained what Femto Engineering does. Since I was working on a project using FEM at the time, it caught my attention for a potential internship. So, I applied and thankfully got the internship for the first half of my 3rd year.

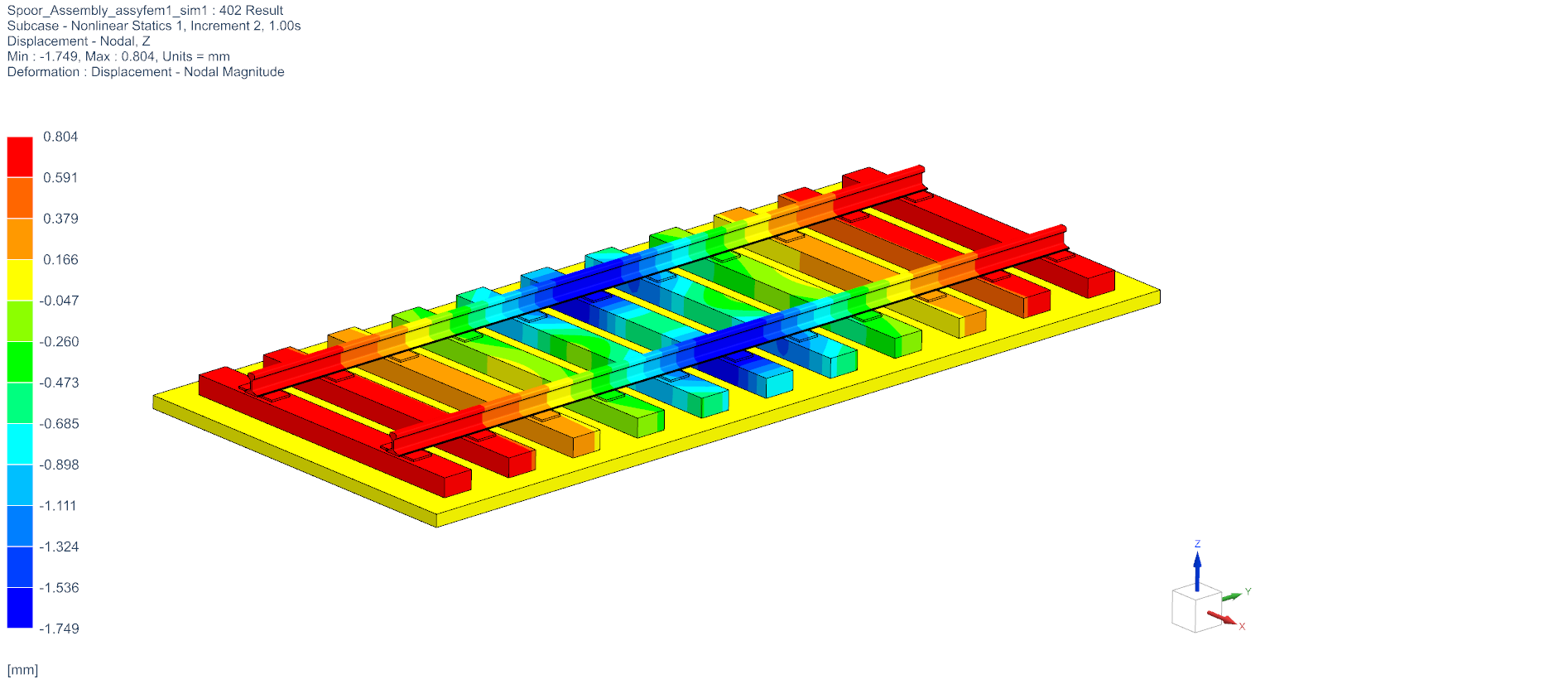

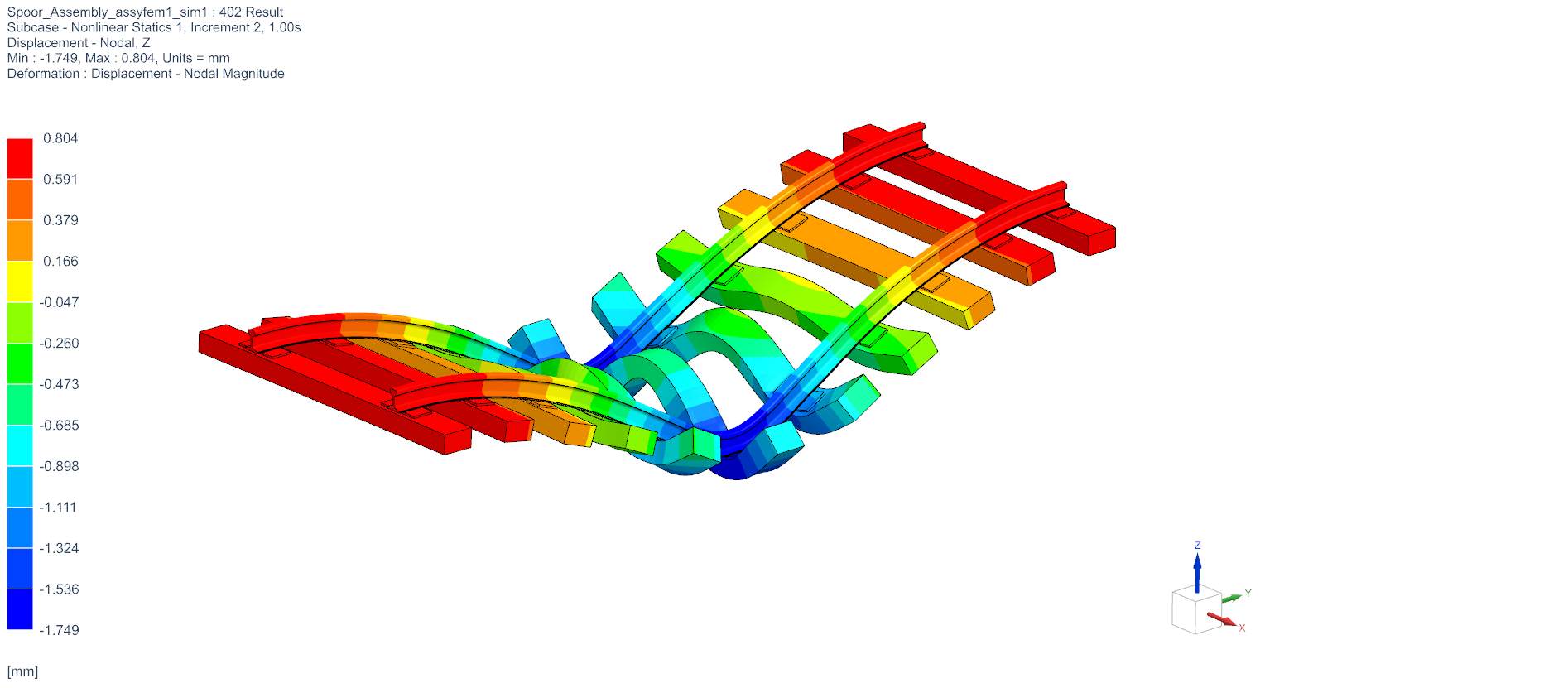

During my internship I worked on plastic railway sleepers. The goal of the assignment was to find out what effects the width of the plastic sleeper has on track ballast settlement. Settlement occurs when the railway has been used a substantial amount of times, and means that the track ballast becomes less damping. To find out what effects the width of the sleeper has on settlement, optimizations were made. This also made clear in which areas of the sleeper material could be saved.

|

|

|

For setting up the model and analyzing the model I used Simcenter 3D. Then for doing the optimizations I used the DSE (Design Space Exploration) program HEEDS, which is an add on of Simcenter 3D.

The most important outcome of this research was the fact that material of the sleepers could be saved whilst no requirements would be violated. By using material in places where it’s most needed, and reducing material where less so, not only result in material savings, but also provide a better stress distribution over the ballast. This has a positive effect on the reduction of settlement and can be increased by using steel bars within the plastic sleepers as support.

Working at Femto Engineering is a good experience because everyone is very helpful. The atmosphere is very casual, but serious when necessary.

I have always had an interest in technical designs, and in particular the technical designs of cars. So, after graduating high school I started studying Automotive Engineering at the Rotterdam University of Applied Science. I am currently in my 3rd year and enjoying the learning curve of becoming an engineer.

Thanks Jochem for sharing your story! We want to thank you for your hard work and enthusiasm.

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!